D2d international

Complete vertical Manufacturing Facility

Our sprawling manufacturing facility is equipped with cutting-edge technology and modern machinery, creating an environment that fosters creativity and ingenuity. With dedicated sections for each stage of the garment production process, from pattern making to stitching and finishing, we ensure a seamless workflow that brings your designs to life.

We have invested in the latest industrial sewing machines, automated cutting systems, and computer-aided design (CAD) software to optimize precision and reduce lead times. Our specialized equipment enables us to handle a diverse range of fabrics, intricate designs, and customized orders with utmost proficiency.

MONTHLY MANUFACTURING CAPACITY

-

01 - YarnWe source top-quality combed yarn from the industry-leading spinning mills around our facility.

01 - YarnWe source top-quality combed yarn from the industry-leading spinning mills around our facility. -

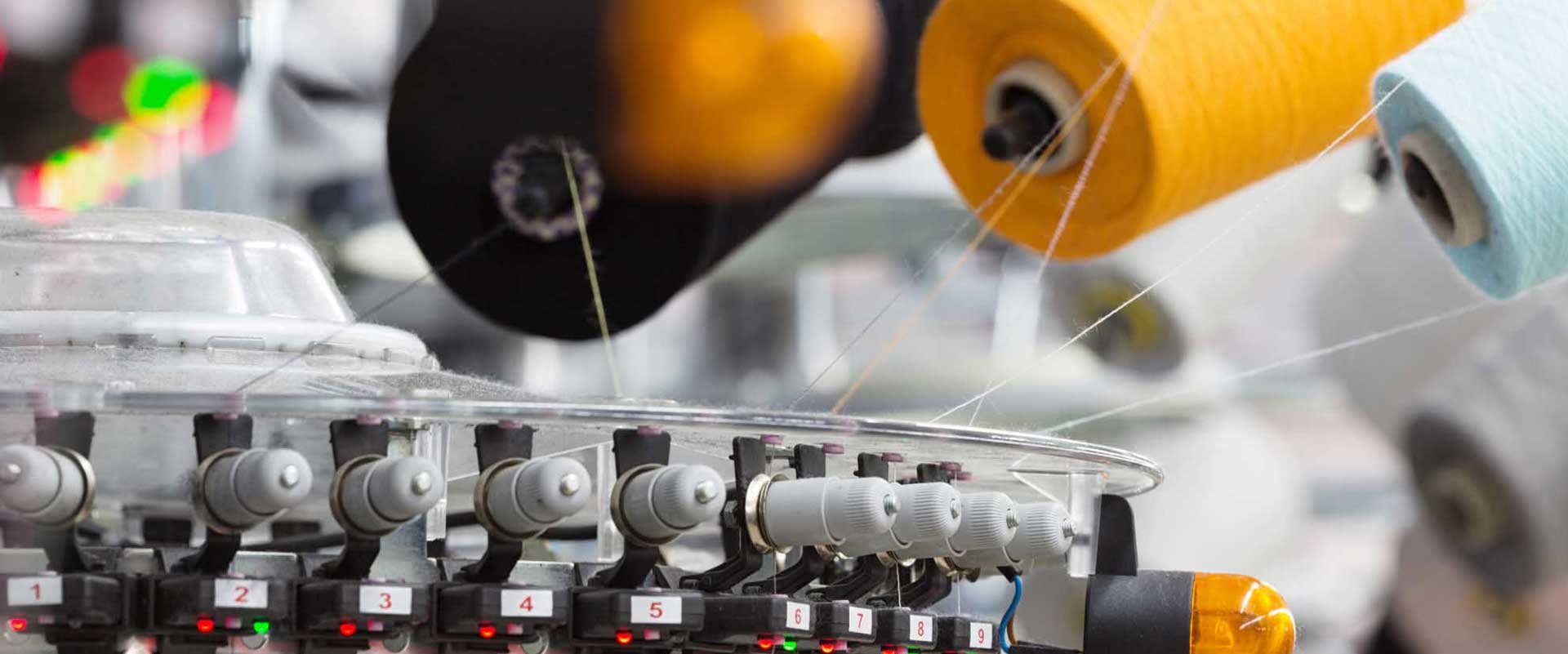

02 - KnittingOur knitting division is equipped with advanced machines from Germany’s Mayer & Cie with a monthly capacity of 100 tons, capable of producing cotton and cotton blends like polyester, viscose, and modal fabrics. We can produce single jersey, single jersey with elastane, interlock, brush back, loop back, 1x1 rib, 2x2 rib, waffle, yarn dyed and jacquard fabrics. Special finishes like sueding, peaching, and raising could be done based on the customers’ requirements.

02 - KnittingOur knitting division is equipped with advanced machines from Germany’s Mayer & Cie with a monthly capacity of 100 tons, capable of producing cotton and cotton blends like polyester, viscose, and modal fabrics. We can produce single jersey, single jersey with elastane, interlock, brush back, loop back, 1x1 rib, 2x2 rib, waffle, yarn dyed and jacquard fabrics. Special finishes like sueding, peaching, and raising could be done based on the customers’ requirements. -

03 - DyeingD2D Processing division is a future focused company providing professional dyeing services and was incorporated in the year 2020 as a subsidiary firm of D2D International.

03 - DyeingD2D Processing division is a future focused company providing professional dyeing services and was incorporated in the year 2020 as a subsidiary firm of D2D International.DYEING

Our full-fledged processing and finishing unit can process both tubular and open width fabrics.

PRODUCTION CAPACITY

AUTOMATIC DYEING MACHINE - 20 TONS / DAYFINISHING TUBULAR - 12 TONS / DAYFINISHING OPEN WIDTH - 12 TONS / DAYHEAT SETTING

We can proudly say that we are equipped with India’s One & Only 10 chamber stenter finish machine from Germany’s Monfongs and that gives best finish for cotton blend fabrics including double padding dip wash, weft straightening and 10 Chamber stenter processes to get the great finish to our knitted fabrics.

TESTING LAB

All our fabrics and accessories are tested in our in-house and third-party laboratories such as SGS, ITS and BV to make sure they meet the customer requirements.

Download E Brochure -

04 - PRINTINGOur well-equipped printing plan consists of both manual and automated printing machines from S-ROQ, Portugal with a capacity of 40 thousand impressions per day.

04 - PRINTINGOur well-equipped printing plan consists of both manual and automated printing machines from S-ROQ, Portugal with a capacity of 40 thousand impressions per day.Types of Printing:

- Pigment Prints

- Non – PVC Print

- Discharge Print

- Flock Print

- Foil Print

- Glitter Print

- Radium Print (Glow In Dark)

- Sublimation Print

- Hi Density Print

-

05 - EMBROIDERY

05 - EMBROIDERYModern machinery from Barudan (Japan) along with a highly technical work force could deliver a variety of embroidering techniques including Bridge laser, hand sequence and manual embroidery could deliver up to 10 thousand pieces per day.

-

06 - MANUFACTURING

06 - MANUFACTURINGFABRIC EVALUATION

Our rigorous fabric evaluation process ensures that every garment we create meets the highest standards of comfort, durability, and style. From the moment we source the fabric to the final stitch, our commitment to excellence shines through every step of the way.

CUTTING

Our leading-edge morgan automated cutting machine from Italy can cut up to 100 thousand pieces per day.

SEWING / CHECKING / PACKING

We are equipped with 40 sewing lines with advanced Japanese built sewing machines like Brother, Juki, Yamato, Pegasus, and Kansai operated by our adept workforce help accelerate the production.

QUALITY ASSUARANCE

Our commitment to quality is unwavering. Our infrastructure houses a dedicated quality assurance department that conducts rigorous inspections at various stages of production.

METAL DETECTION ZONE

We ensure that every garment passes through a metal detector prior to our packing, keeping in mind the safety norms to avoid the menace of small metal particles mainly comes from sewing needles.

RFID

We leverage cutting-edge technology to enhance efficiency, accuracy, and traceability in garment Manufacturing. One of the key innovations we utilize is Radio-Frequency Identification (RFID) Scanning. RFID Technology has revolutionized the way we manage and track garments throughout the production process, ensuring superior quality and streamlined operations.

WAREHOUSE

We have 250 tons of fabric storing capacity & we use Toyota’s advanced pneumatic machine for handling our fabric rolls to place in our shelves by eliminating human stress successfully.

-

07 - QUALITY POLICY & STANDARDS

07 - QUALITY POLICY & STANDARDSAt D2D, quality is not just a measure; it’s a commitment ingrained in every stitch, seam, and detail of our garments. We believe that exceptional quality is the cornerstone of customer satisfaction and business success. Our relentless pursuit of perfection drives us to uphold the highest standards across every aspect of our operations. Our Quality Policy is “Crafting Excellence, Stitch by Stitch”. We strive to achieve this by practicing the Lean manufacturing & Barcode system in our production lines to increase our efficiency and at the same time to reduce the mistakes.

-

08 - SKILLED WORKFORCE

08 - SKILLED WORKFORCEBehind every successful garment, there’s a team of skilled artisans and professionals. Our workforce consists of experienced pattern makers, tailors, quality control experts, and designers who share a passion for creating exceptional garments. Their dedication and attention to detail ensure that every piece leaving our facility is a masterpiece.